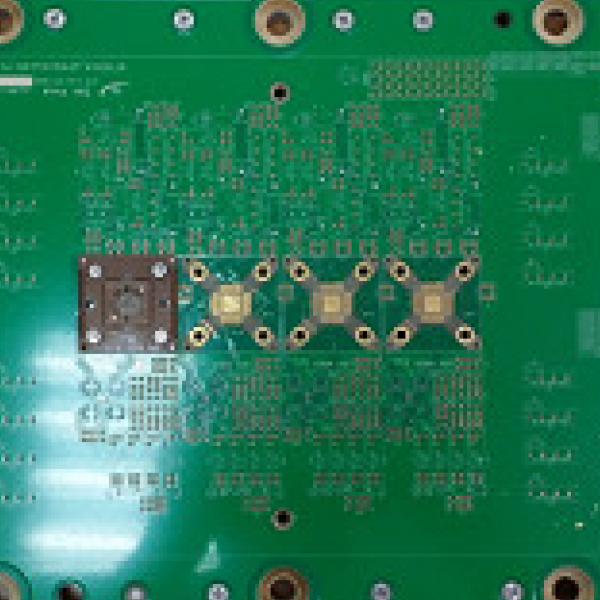

TS1202ALogic – Load Board

Circle automatic correction (single/multi-part)

Autofocus

Multi workpiece cutting

Programmable light source

Modular design

Tool interchangeability

With 15" color touch screen

Rich experience in cutting machine related cutting applications

Product Specifications

Through the Test program, the test signal of each pin is transmitted to the Socket through the POGO pin to the Device / package. FT verification test.

※The efficiency of cutting capacity is improved

- When returning to the next tool after machining, the three axes (X-Y-Z axis) move simultaneously

- ΘThe shaft structure is improved (the height is reduced), making the machine more stable during cutting

- Non-contact cutting edge length detection (NCS) operation time is reduced by about 10 seconds

※The operation and maintenance of the machine is more convenient

- Wide discharge door

- New tool holder design reduces cutting debris from adhering to the BBD sensor or workpiece

- Non-contact edge length sensor (NCS) position moved to the back of the sink

- (Optional) A tool holder with a two-fluid nozzle can be configured for workpieces requiring high cleanliness

※Software scalability

- You can connect two different cutting parameters in series to apply the same workpiece to be cut at the same time and perform automatic cutting