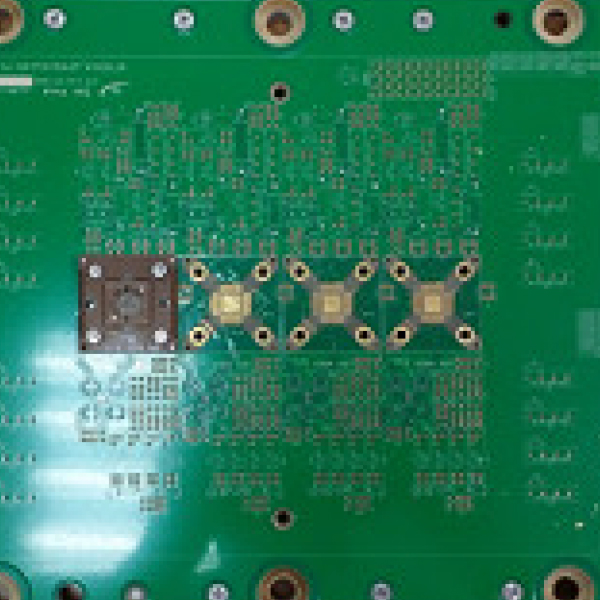

TS1202ALogic – Load Board

Circular Auto Calibration (Single/Multi-Workpiece)

Auto Focus

Multi-Workpiece Cutting

Programmable Light Source

Modular Design

Tool Interchangeability

Equipped with a 15" Color Touchscreen

Extensive experience in various cutting applications

Product Specifications

Through the test program, the test signals of each pin are transmitted from the POGO pin to the socket and then to the device/package for FT verification testing.

※Improved Cutting Efficiency

- After processing, the three axes (X-Y-Z axis) move together to return to the next cutting position.

- Θ-axis structure has been improved (height reduced) to enhance stability during cutting.

- Non-contact detection of blade length (NCS) reduces operation time by approximately 10 seconds.

※Easier Machine Operation and Maintenance

- Wider material feeding door.

- Innovative blade holder design reduces cutting residues adhering to BBD sensors or workpieces.

- Non-contact blade length sensor (NCS) relocated to the rear of the water tank.

- (Optional) For workpieces requiring high cleanliness, a blade holder with a dual-fluid nozzle can be provided.

※Software Scalability

- Ability to simultaneously link two different cutting parameter sets for the same workpiece and perform automatic cutting.